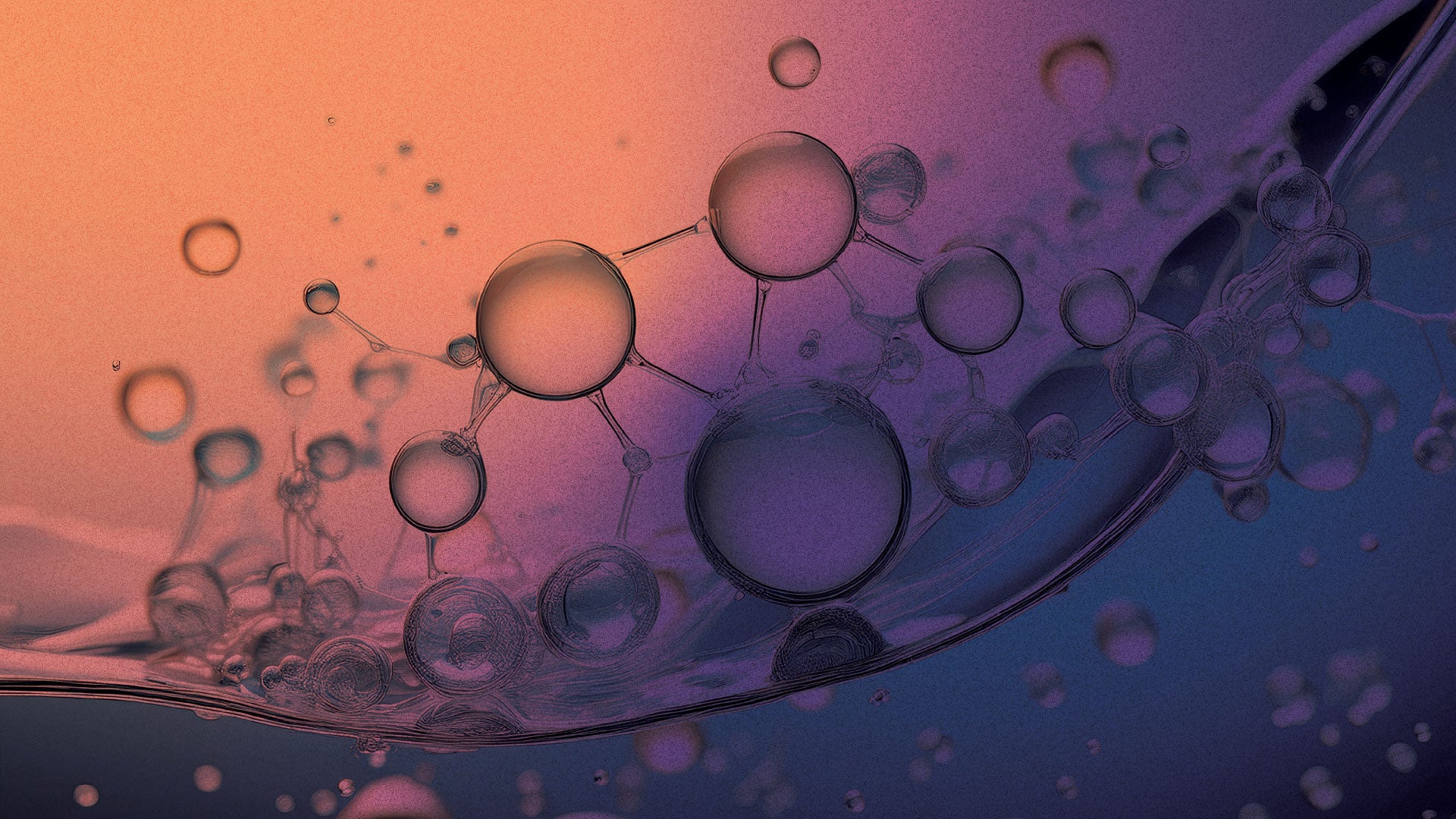

- In Plain English: Emulsions are usually mixtures of oil and water – think about salad dressing, and how the oil will separate from the rest of the dressing if you let it sit for a while. When the salad dressing is shaken up that means the oil is “mixed” back into the dressing – that mixture is an emulsion (a combination of oil and water).

- Technical Answer: Emulsions are mixtures of two immiscible liquids, with one being dispersed within the other. For example: oil and water are immiscible, but the addition of an emulsifier and specific processing allows oil droplets to stay dispersed throughout water, instead of separating into distinct layers.

- In Plain English: We use equipment that applies a huge amount of pressure to the emulsion; double than at the bottom of the ocean. This pressure stabilizes the emulsion, making tiny oil (cannabinoid) droplets that are all very similar in size. These droplets repel each other (like how magnets repel each other) – and this repelling keeps the droplets evenly spread out and stable.

- Technical Answer: Utilization of high pressure homogenization, and its associated sheer forces, exert sufficient energy to yield high levels of droplet particle size consistency. Combined with the inherent surface chemical properties of the emulsifiers, the resulting zeta potential ensures that encapsulations remain evenly dispersed throughout the emulsions’ water base.

- In Plain English: Unlike salad dressing that will separate over time, we use specialized ingredients and processing so the oil (cannabinoids) stay mixed into your drink. Basically, each tiny oil droplet is “wrapped” in a shell – this is the emulsifier – and that shell allows the oil to go into your beverage without separating.

- Technical Answer: The carbohydrates used to form the cannabinoid and carrier oil droplets’ encapsulations have a hydrophobic end (attracted to the oil phase) and hydrophilic end (attracted to the surrounding solution). The zeta potential and polydispersity index of the droplets are sufficient to ensure even, stable dispersion when diluted within a beverage.

- In Plain English: Our emulsions are mostly water – it’s concentrated, so when you add it to your product as an ingredient, you’re basically diluting it down so that you have your target amount of oil (cannabinoids) in each serving. They were designed to be compatible with most manufacturing setups and simple to pour and mix.

- Technical Answer: Diluting the emulsion reduces its active content’s relative potency; calculated dilution within a water base allows for precise, per-serving dosage of the active ingredient. Sufficient agitation disperses the emulsion equally within the product base, and its zeta potential ensures even dispersion is maintained.

- In Plain English: The emulsifier that we mentioned before also acts as a “wall” between the oil (cannabinoids) and everything around it (your beverage). That wall can block the taste and smell of the oil from being noticed when someone smells, and then drinks or eats, your product.

- Technical Answer: The selection of a proprietary blend of carrier oils dilutes the relative concentration of flavonoids and terpenoids, and the proprietary blend of gum arabic emulsifiers form an interfacial film, creating a barrier between the flavonoids and terpenoids from being perceived by the consumer.

- In Plain English: When your body digests oil, it takes time to recognize it, and then make compounds that will break the oil down into droplets, and then make more compounds that bring those droplets into your bloodstream. We are, in a sense, pre-digesting the oil (cannabinoids) so that your body recognizes and absorbs it faster.

- Technical Answer: The selection of emulsifiers resistant to dissolution of the interfacial film within the stomach’s pH, but less so in the small intestine, accelerates delivery of droplets to the most efficient absorption points. Chemical similarities between the emulsifiers and bile salts accelerate enzyme recognition of oil droplets, enhancing bioavailability.